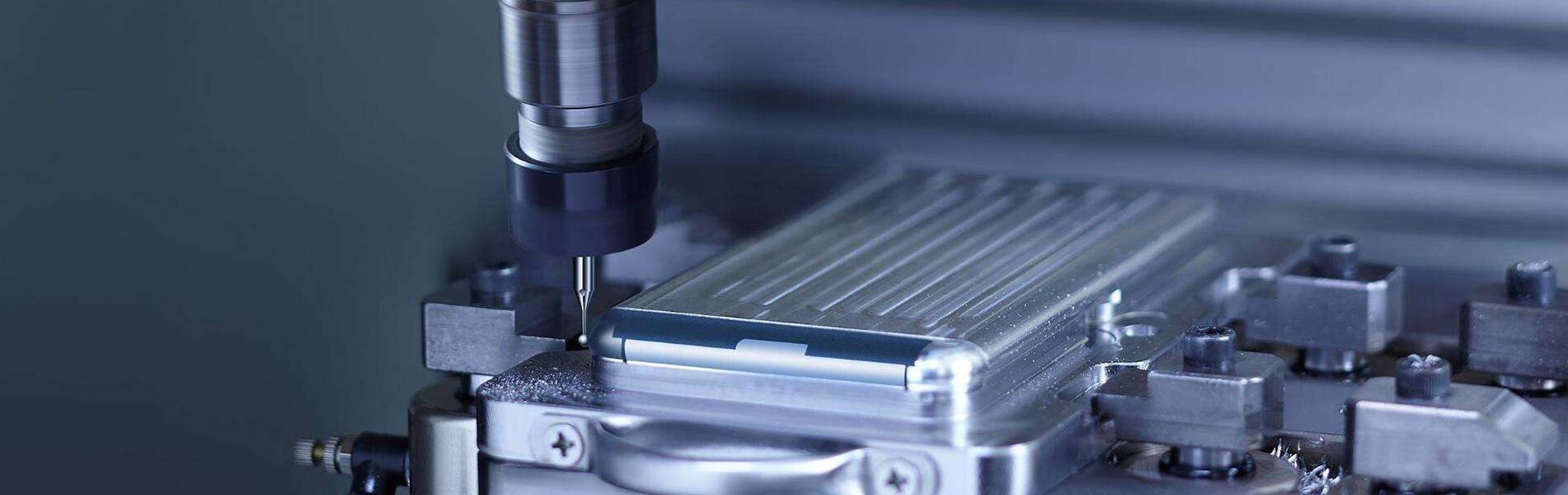

Why is the tool setting instrument so important?

In the process of workpiece processing, auxiliary time such as workpiece loading and unloading, tool adjustment, etc., account for a considerable proportion of the processing cycle. The tool adjustment is time-consuming and laborious, and not easy to be accurate, and finally requires trial cutting. Statistics show that for the processing of a workpiece, pure maneuvering time only accounts for 55% of the total time, and auxiliary time such as clamping and tool setting accounts for 45%. Therefore, in the machining process, the tool setting instrument is extremely important.

So, how does the tool setting instrument work?

1.Measure and compensate tool offset value in five directions of ±X, ±Z and Y axis

The measurement and compensation of tool offset values in five directions can effectively eliminate errors and low efficiency caused by manual tool setting. No matter what kind of cutting tool is used, when turning or milling the workpiece contour, all the tool tip points or tool axis lines involved in the cutting must be adjusted or compensated to accurately locate the same theoretical point or axial lead. For powered rotary tools, except to measure and compensate the offset value in the length direction of the tool, it is also necessary to measure and compensate the offset value in the diameter direction of the tool (the offset value of the two radii delimited by the axis line of the tool). Otherwise, the machine tool cannot process a workpiece with the correct size. On a machine without a tool setting instrument, the offset value of each tool was obtained by careful test cutting of each tool and measurement, calculation and compensation (manual tool setting) of the workpiece size. It is laborious, and the workpiece will be scrapped if you are not careful. When the tool is changed, the work has to be repeated. Therefore, tool setting is one of the tasks that takes the longest time for machine tool assistance.

After a tool setting instrument was used, the offset value of the tool to the workpiece coordinate system can be automatically set after the tool setting, thereby automatically establishing the workpiece coordinate system. In this case, there is no need to use "G50 command" to establish the workpiece coordinate system in the processing program.

2. Automatic monitoring, alarm and compensation of tool wear or damage during processing

It is very troublesome to complete the wear value compensation on the machine without the tool setting instrument. It is necessary to stop the machine many times to manually measure the size of the workpiece, and manually modify the tool compensation parameters with the obtained wear value. After installing the tool setter, this problem is much simpler. As long as you set how many machining cycles are completed in the program and execute an automatic tool setter, the tool compensation work can be completed.

For tool breakage alarm or tool wear to a certain extent, it is to set a "threshold value" according to the allowable amount of tool wear. Once the error detected by the tool setter exceeds the threshold value, it is considered that the tool is damaged or exceeds the allowable value. If the wear value is higher, the machine will automatically alarm and stop, and then forcibly replace the tool.

3. Compensation of tool offset value change caused by thermal deformation of machine tool

During the working cycle of the machine, the various heat generated will cause the deformation of the machine, especially the thermal elongation of the lead screw, and change the position of the tool tip. As a result, the dimensional accuracy of the processed workpiece will be affected. Install the tool setter on the machine, regard the change in the position of the tool tip caused by thermal deformation as the wear value of the tool, and measure the tool offset value by the tool setter to solve the problem.

In order to reduce the auxiliary time of the machine, reduce the rework and scrap rate, and better serve customers, Far East Tech has introduced the ZOLLER SMILE tool setting instrument. If you have any requests, please do not hesitate to contact us!

Categories

New Blog

© Copyright: 2024 Far East Tech CO., Ltd. All Rights Reserved.

IPv6 network supported