How much do you know about the quenching process? Part 1

It is well known that heat treatment is a common method for changing the mechanical properties of certain metals. Being able to change the hardness, toughness, and strength of a metal while keeping its chemical composition intact and nearly unchanged is a great way to tailor a metal to the needs of the environment and job. There are many different ways to heat treat metals, the most popular of which is through a method called quenching.

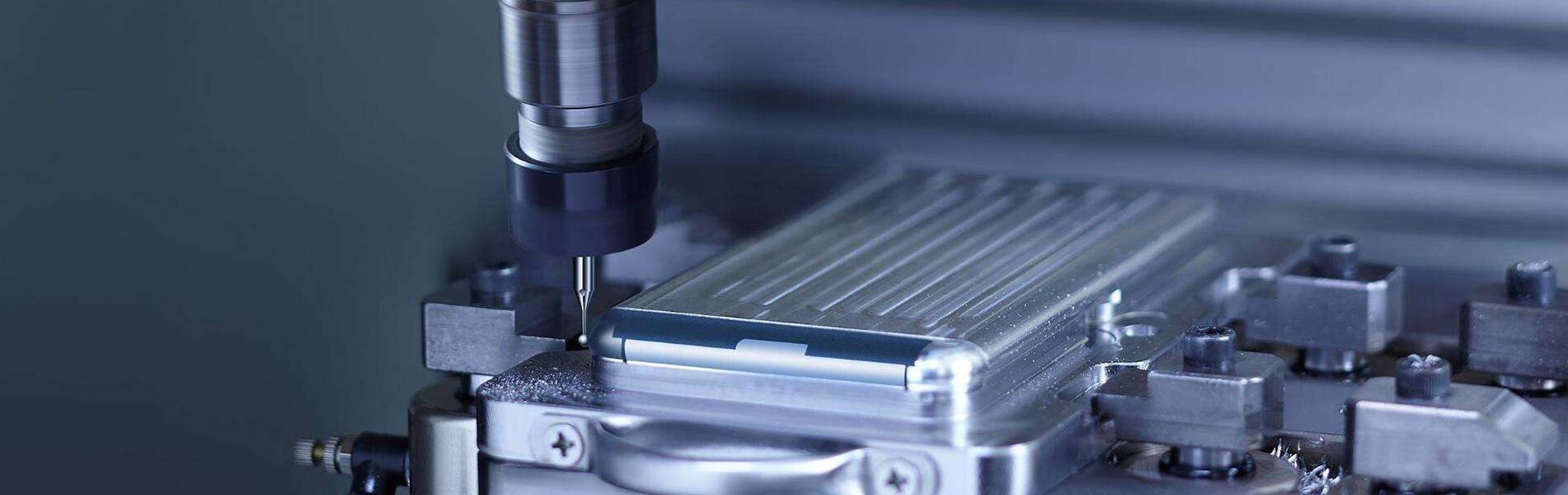

Quenching is a metal heat treatment process. The solution treatment of aluminum alloy, copper alloy, titanium alloy, tempered glass and other materials or the heat treatment process with rapid cooling process is also called quenching. Quenching refers to the rapid cooling of metals to adjust the mechanical properties of their original state. To perform the quenching process, the metal is heated to a temperature above normal conditions, usually some temperature above its recrystallization temperature but below its melting temperature. In order for the heat to "soak" the material, the metal can remain at this temperature for a period of time. Once the metal is kept at the desired temperature, it is quenched in the medium until it returns to room temperature. The metal can also be quenched for an extended period of time so that the cooling from the quenching process is distributed throughout the thickness of the material.

Quenching can improve the hardness and wear resistance of metal workpieces, so it is widely used in various tools, molds, measuring tools and parts that require wear-resistant surfaces (such as gears, rolls, carburized parts, etc.). Through the combination of quenching and tempering at different temperatures, the strength, toughness reduction and fatigue strength of the metal can be greatly improved, and the coordination between these properties (comprehensive mechanical properties) can be obtained to meet different application requirements.

Categories

New Blog

© Copyright: 2026 Far East Tech CO., Ltd. All Rights Reserved.

IPv6 network supported