How to get the overall heat treatment parts?

Commonly used heat treatment methods include integral heat treatment, surface heat treatment and deformation heat treatment. The overall heat treatment is the "four fires" that people often hear in the factory, which refers to the four most commonly used heat treatment methods: annealing, normalizing, quenching and tempering. Among them, quenching and tempering are closely related and are often used together. Indispensable. With the different heating temperature and cooling method, the "four fires" have evolved different heat treatment processes, including modulation, aging treatment and deformation heat treatment.

There is also the term quenched and tempered steel, which is formed by adding manganese and silicon elements when smelting steel. Quenched and tempered steel is not the steel that has been quenched and tempered, so pay attention to the difference.

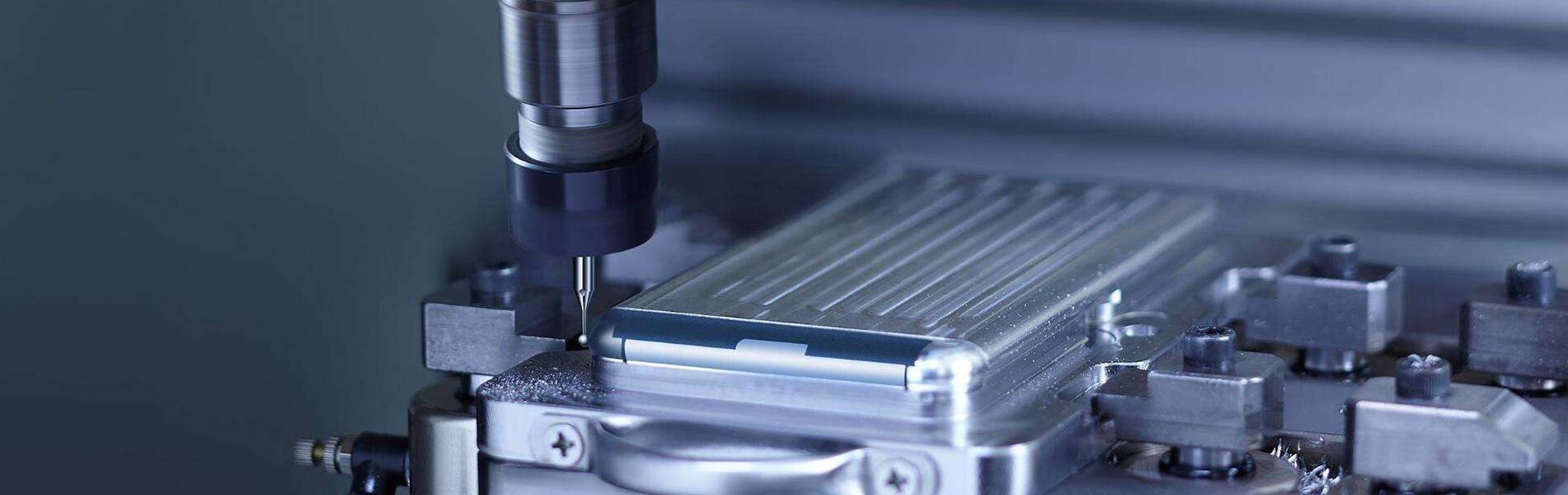

Far East Tech Co., Ltd. has more than 15 years of experience in precision machining. Our team has rich professional knowledge and skilled processing technology, which has been recognized by many domestic and foreign enterprises. For more information please contact us.

Categories

New Blog

© Copyright: 2026 Far East Tech CO., Ltd. All Rights Reserved.

IPv6 network supported