How to restore a failed precision mechanical part?

First of all, the surface of the workpiece needs to be pretreated, and the degree of bonding between the coating and the base material (workpiece material) is the key. If the bonding cannot be performed or the bonding strength is not enough, the spray coating will be peeled off from the substrate, failing to meet the requirements of repairing parts. Therefore, in order to better combine the coating and the base material, it is necessary to turn or grind the surface of the target workpiece, remove the original spray layer and original treatment layer (such as carburized layer, quenching layer) on the workpiece, and remove various damages and burrs, correct uneven wear on the surface, reserve the thickness of the spray coating, etc. Then remove all the dirt on the surface of the workpiece and do roughening treatment. The roughening process has different methods for different workpieces, mainly including sandblasting, threading or knurling, electric brushing and so on. Next, preheating is required, which is to reduce the temperature difference between the coating and the surface of the workpiece, thereby reducing the residual stress between the coating and the substrate due to thermal expansion differences, avoiding cracking of the coating, and improving the bonding strength of the coating and the substrate material. The temperature control of preheating depends on the size, shape and material of the workpiece, as well as the thermal expansion coefficient of the substrate and coating material. This step is a very important process.

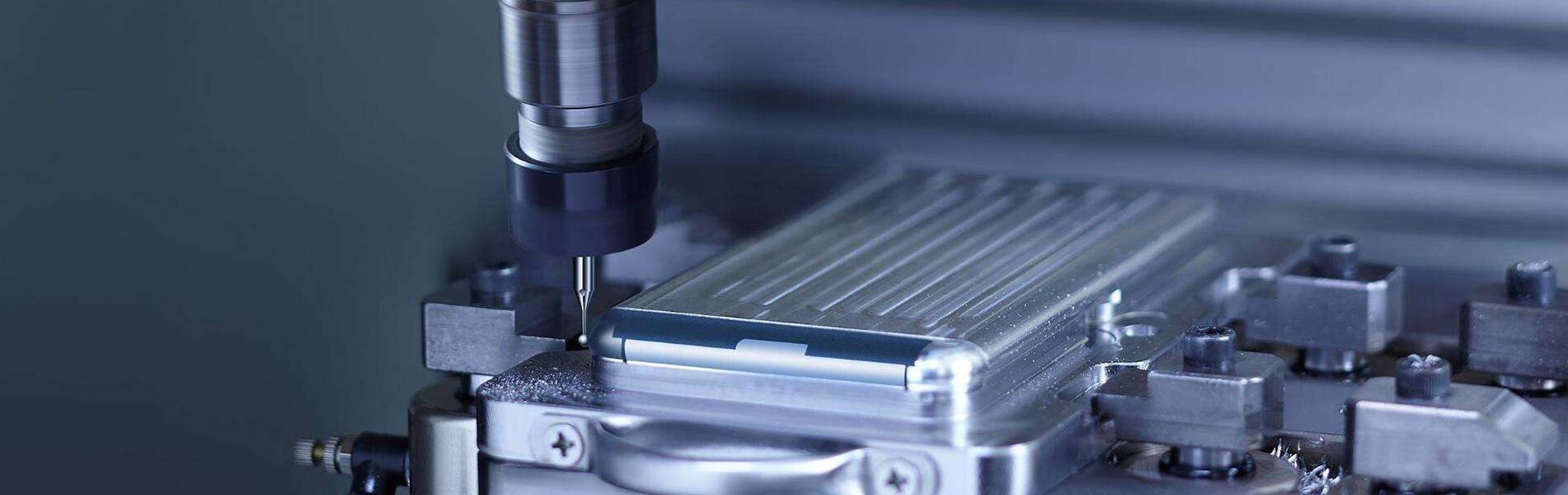

Then there is spraying. Different coating functional requirements determine different spraying materials, different spraying materials determine different spraying processes, and different spraying environments determine different spraying methods. For example, plasma spraying is the best choice for spraying ceramic coatings, high-speed flame spraying can be used for spraying carbide cermet coatings and flame spraying can only be used for spraying plastics. After the coating is sprayed, most of them cannot be used directly, and various follow-up treatments are required. For example, for the coating of the anti-corrosion layer, it is necessary to carry out sealing treatment, because from a microscopic point of view, the molten particles of the spray material will inevitably form small holes when they adhere to the substrate, and these small holes will allow the corrosive medium to penetrate into the base layer, so it must be sealed after spraying. According to the processing experience of Far East Tech Technology, after adjusting the process and performing multiple multi-layer spraying, the small holes connected to the substrate can basically be eliminated, but in order to ensure the maximum quality, the hole sealing treatment is still carried out.

Far East Tech Technology Drilling has many years of experience in precision machining. The company is equipped with professional precision machining equipment and testing equipment and a professional machining team to provide customers with one-stop service, which has been recognized by many Chinese and foreign customers. For more information, Please contact us.

Categories

New Blog

© Copyright: 2026 Far East Tech CO., Ltd. All Rights Reserved.

IPv6 network supported