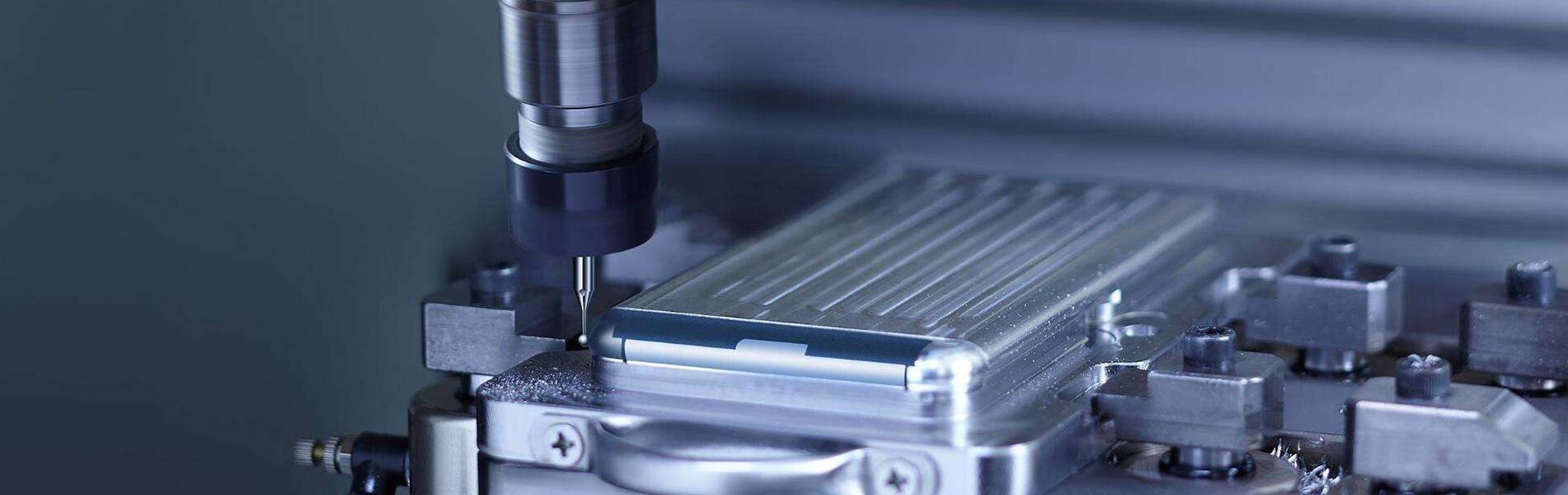

The mirror polishing process is mainly used to reduce the surface roughness of the workpiece. When selecting a polishing process for a metal workpiece, different methods can be selected according to different needs. The following are several common methods of polishing mirror processing.

1. Mechanical polishing Mechanical polishing is a polishing method that obtains a smooth surface by cutting and plastic deformation of the surface of the material to remove the polished convex part. Generally, whetstone strips, wool wheels, sandpaper, etc. are used, mainly manual operation, and special parts such as rotary For the surface of the body, auxiliary tools such as a turntable can be used, and ultra-fine grinding and polishing can be used for those with high surface quality requirements.

2. Chemical polishing Chemical polishing is to make the microscopically protruding part of the material in the chemical medium dissolve preferentially over the concave part, so as to obtain a smooth surface. The main advantage of this method is that it does not require complex equipment, can polish workpieces with complex shapes, and can polish many workpieces at the same time, with high efficiency.

3. Electrolytic polishing The basic principle of electrolytic polishing is the same as that of chemical polishing, that is, by selectively dissolving the tiny protrusions on the surface of the material to make the surface smooth. Compared with chemical polishing, the effect of cathodic reaction can be eliminated, and the effect is better.

4. As a new polishing process, Haokeneng mirror processing equipment has unique advantages in the processing of many kinds of metal parts. It can replace the traditional grinding machine, rolling, boring and rolling, honing, polishing machine, belt sander and other metal surface finishing equipment and processes; it makes the high-finish processing of metal workpieces easy.

5. Ultrasonic polishing Put the workpiece into the abrasive suspension and put it in the ultrasonic field together, and rely on the oscillation of the ultrasonic wave to grind and polish the abrasive on the surface of the workpiece. The macroscopic force of ultrasonic processing is small, and it will not cause deformation of the workpiece, but it is difficult to make and install the tooling. Ultrasonic machining can be combined with chemical or electrochemical methods.

6. Fluid polishing Fluid polishing relies on high-speed flowing liquid and the abrasive particles it carries to scour the surface of the workpiece to achieve the purpose of polishing. Commonly used methods are: abrasive jet machining, liquid jet machining, hydrodynamic grinding, etc.

Far East Tech Technology has more than 15 years of experience in precision machining. The mirror polishing process is stable, and it is equipped with professional processing machines and technical teams to provide customers with one-stop high-quality services. For more information, please contact us.