What are the processing advantages of turning and milling machine tools?

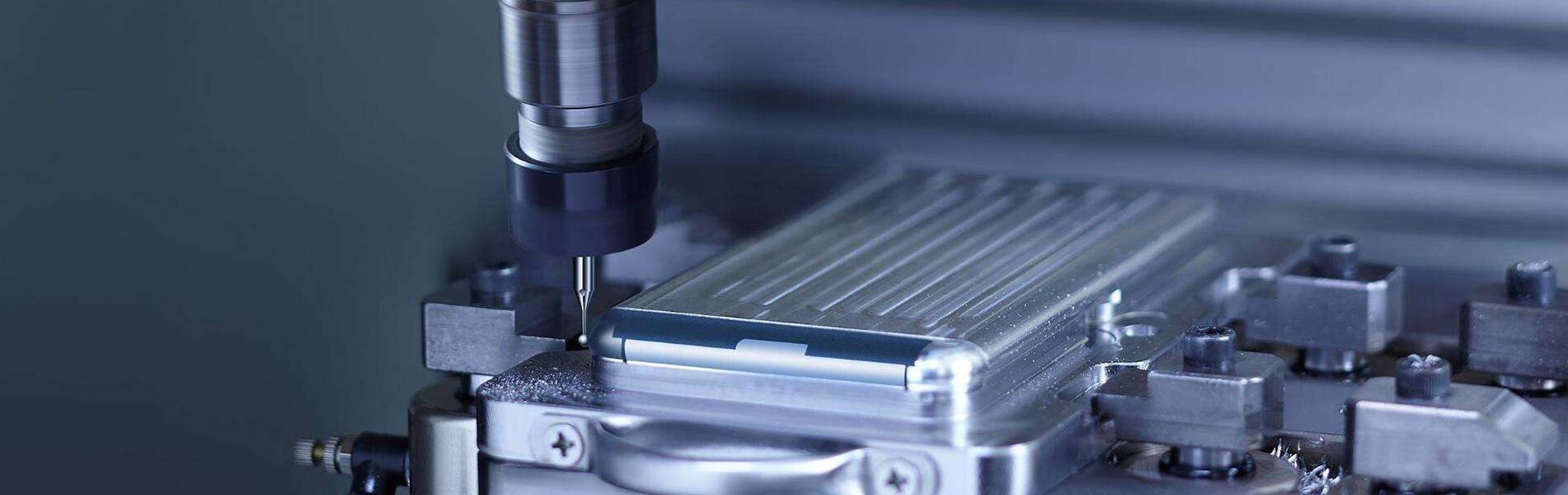

Mill-turn machines are capable of rotating work piece operations (turning) and rotating tool operations, such as milling and cross-drilling, the machine can often be identified as a horizontal or vertical machine, and can be used in some or all tool positions for milling and drilling the spindle. Parts (turning and milling machining part) that require various operations can be machined in one unit, especially if the sub-spindle allows the part to pass from one spindle to another during machining. The recent introduction of economical turn-mill machines, i.e. a shift from a lathe design to something more like a hybrid machine, combines the machine's chuck and spindle with the travel and milling power of a machining center.

The machine tool has an on-line processing diameter of 25.6 inches and a bed length of 39.4 inches. It has the intelligent technology of Dahongmao and various efficiency characteristics. Optional five-axis machining is available for complex milling operations. It also comes with OSP-p300 control with 19-inch monitor and OSP kit and ECO kit apps.

Far East Tech Technology has more than 15 years of experience in precision machining and has great advantages in turning and milling. The company is equipped with professional precision machining equipment and testing equipment to provide our customers with one-stop service, and has won many Chinese and foreign customers. The quality of our processed products can refer to the product list on our website, if you want to know more, please contact us.Categories

New Blog

© Copyright: 2026 Far East Tech CO., Ltd. All Rights Reserved.

IPv6 network supported