The definition of the burr

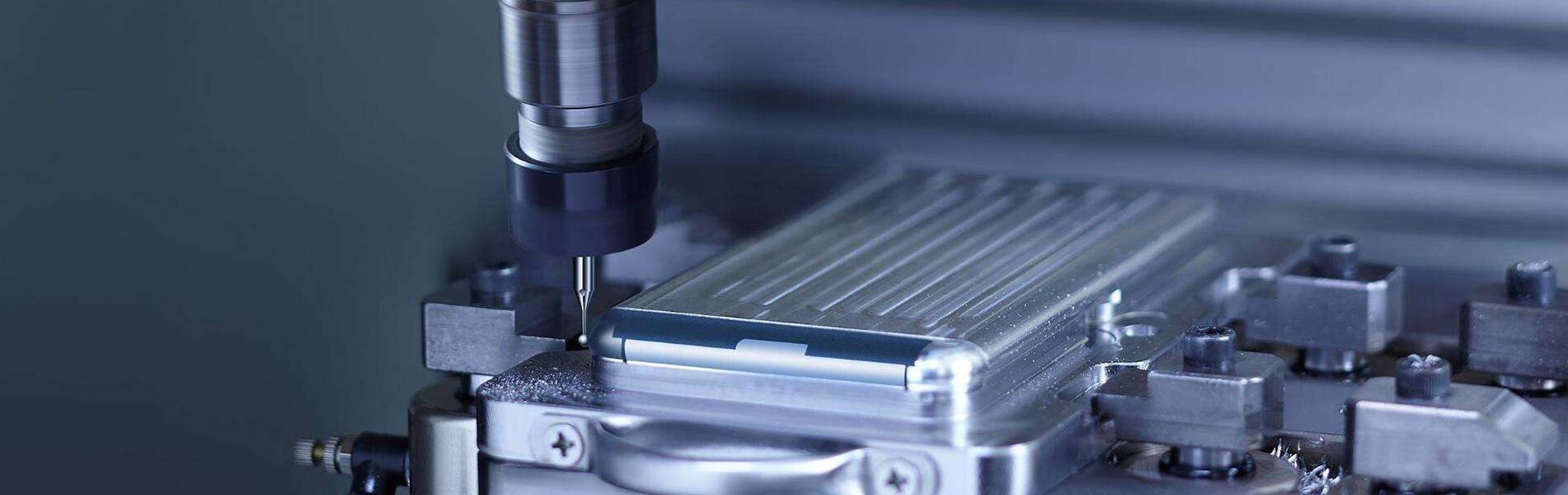

Burr is a protrusion of a material, such as metal or resin that is generated when it is processed. Burrs are created from shearing, bending, cutting, piercing, and compressing materials that are mostly seen on soft and ductile materials. About the burr size, we express burr size by its height, thickness and length. And the deburring is a secondary operation of a machining process that enhances the final quality of the product by removing raised edges and unwanted pieces of material, known as burrs, left by the initial machining processes.

Hazards of burrs

Burrs are an inevitable product of metal processing and are difficult to completely avoid. The existence of burrs not only affects the appearance of the product but also affects the assembly and performance of the product, accelerates the wear between the equipment, and reduces the service life. With the development of high technology and the improvement of product performance, the requirements for product quality are becoming more and more strict, and it is more and more important to remove the burrs of mechanical parts. The existence of burrs has an impact on product quality and product assembly, use, dimensional accuracy, and shape and position accuracy. So it is necenary to deburr.

The methods of deburring

Deburring is done in a variety of methods that depend on the material, part geometry, size and location of burrs, product volume, and cost. The main methods as :

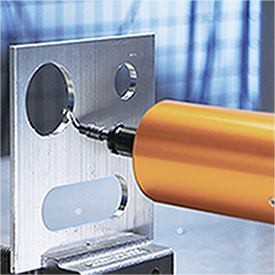

Manual Deburring: This method refers to deburring operations that use hand-held or mechanized tools which use tools such as deburrers, grinders, brushes, files, sanders, and so forth. Robotic Deburring: This involves a chamfering, grinding, or deburring tool mounted on a robotic arm. Mechanical Deburring: Mechanical deburring employs machines to perform a general deburring on the workpiece. Waterjet Deburring: This process utilizes the impact force of high-velocity water jets to erode burrs and debris from the workpiece. Water jets are CNC controlled, similar to tooled robotic systems. Electrochemical Deburring: This is a deburring process that utilizes the principles of electrolysis. Thermal Deburring: This process is also known as thermal energy method. In this process, the workpiece is exposed to hot corrosive gases for a very short period. A thermal shockwave is generated which quickly vaporizes the burr. Cryogenic Deburring: Cryogenic deburring is mostly done on precision plastic parts which possess inherent impact toughness.

Far East Tech Technology has more than 15 years of rich experience in the precision machining industry and has an excellent reputation. The company is equipped with a professional technical team and precision processing machines, which can provide customers with one-stop service. For more information, please contact us.