Precision machined parts will have a certain degree of wear after assembly and operation. Heat treatment can enhance the hardness of the workpiece, increase the wear resistance of the workpiece and prolong the life of the workpiece. In this article, we will introduce to you what is vacuum heat treatment processing technology. Next week, we will introduce the characteristics of vacuum heat treatmen...

We introduced what is vacuum heat treatment in the last batch of articles, and now let's introduce the characteristics of vacuum heat treatment. The vacuum state is an excellent protective environment. The mechanical parts after heat treatment in the vacuum environment are smooth and bright in appearance, the internal structure has been changed, and the mechanical properties are excellent. Its cha...

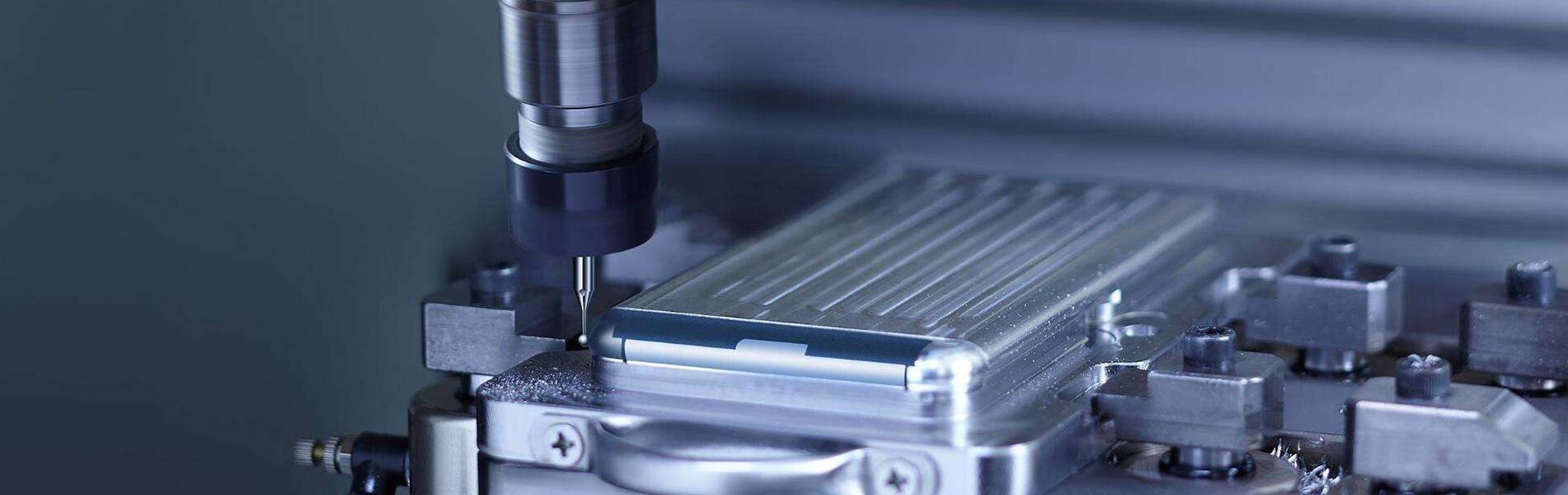

Precision hardware parts processing is a production process that requires very high precision of spare parts. In the process of processing and producing precision hardware parts, the precision must be strictly controlled to ensure that qualified hardware parts are made. So what are the processes of precision hardware parts processing? 1. First of all, you must be familiar with the processing equip...

The definition of the burr Burr is a protrusion of a material, such as metal or resin that is generated when it is processed. Burrs are created from shearing, bending, cutting, piercing, and compressing materials that are mostly seen on soft and ductile materials. About the burr size, we express burr size by its height, thickness and length. And the deburring is a secondary operation of a machinin...

In order to overcome the defects of aluminum alloy products in terms of surface hardness , wear resistance and other defects, so as to expand the scope of application and prolong the service life. Surface treatment of aluminum alloy products has become an indispensable part of the production process. Anodizing technology is currently the most widely used and most successful way. Anodizing refers t...

When CNC roughing, we often use dynamic processing technology to improve processing efficiency. So in the more time-consuming finishing process, is there any way to improve the processing efficiency? Mastercam's Accelerated Finishing superstring finishing technology is the programming solution for efficient finishing with arc cutters. For large arc cutters of various shapes, based on the shape of ...

“Which aluminum alloy bends the best?” is a a common question customers want the answer to. In this post, we’ll explain it to you. BACKGROUND In high purity forms, aluminum is soft and ductile. Bending is a delicate and demanding process most of the time and common fabricating processes require a degree of formability that make your choice of proper alloy critical. Depending on designation, alloys...

Categories

New Blog

© Copyright: 2026 Far East Tech CO., Ltd. All Rights Reserved.

IPv6 network supported