What is the cleanliness of a part or product?

Cleanliness refers to the amount of contaminants remaining on the surface of a part or product after cleaning. The indicators of dirt include type, shape, size, quantity, weight, etc. The specific indicators used depends on the degree of influence of different contaminants on product quality and the requirements for the accuracy of cleaning control.

The purpose of ensuring the cleanliness is to enable the product to reach the specified service life, and not to shorten the service life due to contaminants in the process of manufacture, use and maintenance. By measuring the cleanliness and limiting its numerical value that the damage of contaminants to the product can be avoided or reduced. Commonly used detection methods are as follows:

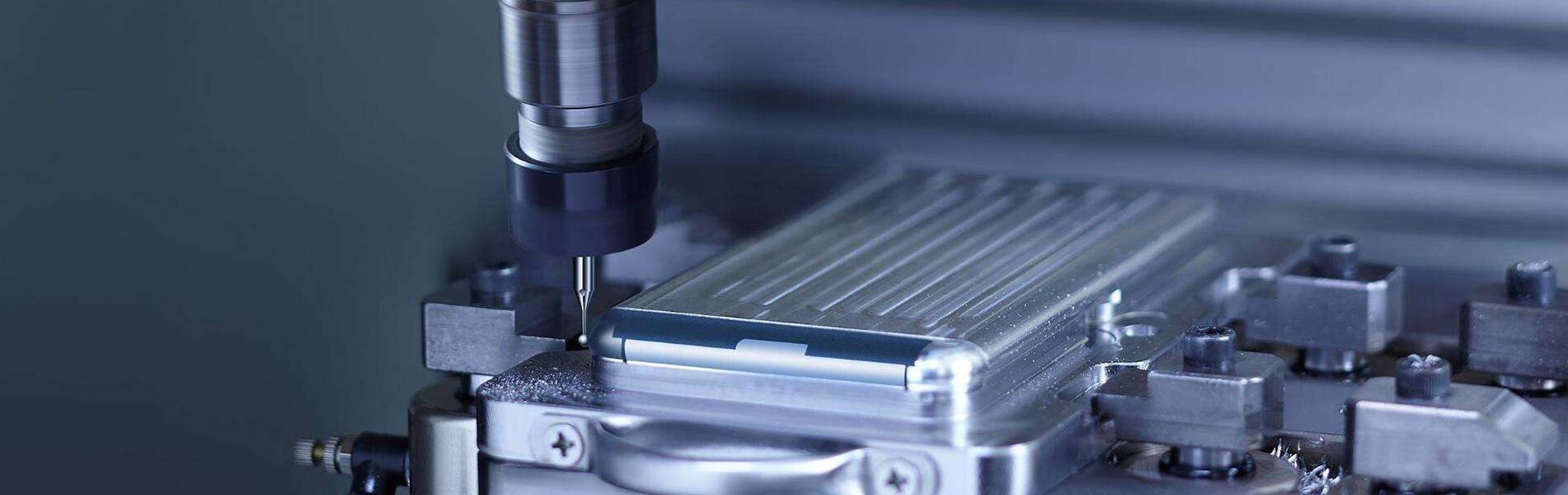

Far East Tech Technology has more than 15 years of rich experience in the precision machining industry and has an excellent reputation. The company is equipped with a professional technical team and precision processing machines, which can provide customers with one-stop service. For more information, please contact us.

Categories

New Blog

© Copyright: 2025 Far East Tech CO., Ltd. All Rights Reserved.

IPv6 network supported