The quality and precision of the finished part is closely related to many elements, and the material is one of them. Steel is widely used in precision machining, and there are many types. Carbon steel: Carbon steel is also called carbon steel, which is an iron-carbon alloy with a carbon content of 2%. In addition to carbon, carbon steel generally contains a small amount of silicon, manganese, sulf...

Salt spray testing is an environmental test that artificially simulates salt spray environmental conditions to assess the corrosion resistance of products or metal materials. Salt mist mainly plays a corrosive role on metal materials, and electrochemical reactions occur with internal metals through chloride ions contained in the salt mist penetrating the oxide layer and protective layer on the met...

Standard parts refer to commonly used components such as threaded parts, keys, pins, rolling bearings, etc. that have been fully standardized in terms of structure, size, drawing, marking, and other aspects and are produced by professional factories. Standard parts can be divided into broad and narrow senses. Generalized standard parts refer to mechanical parts and components with clear standards....

In production, the labor cost of labor is a significant expense. So more and more companies are introducing automation equipment. And more and more different and personalized production needs, only standard automation can no longer meet. So non-standard automation came into being. Non-standard automation, as the name implies, is an automated mechanical production equipment that is tailored and cus...

In the processing of aluminum alloy, we often see similar material codes such as AW5083-R or AL6061. In fact, this is the grade of aluminum alloy. Different grades contain different chemical components, and there are also differences in performance. Several common aluminum alloys are as follows. AL1 series pure aluminum:Series 1 pure aluminum, containing more than 99% aluminum. Such as 1050, its a...

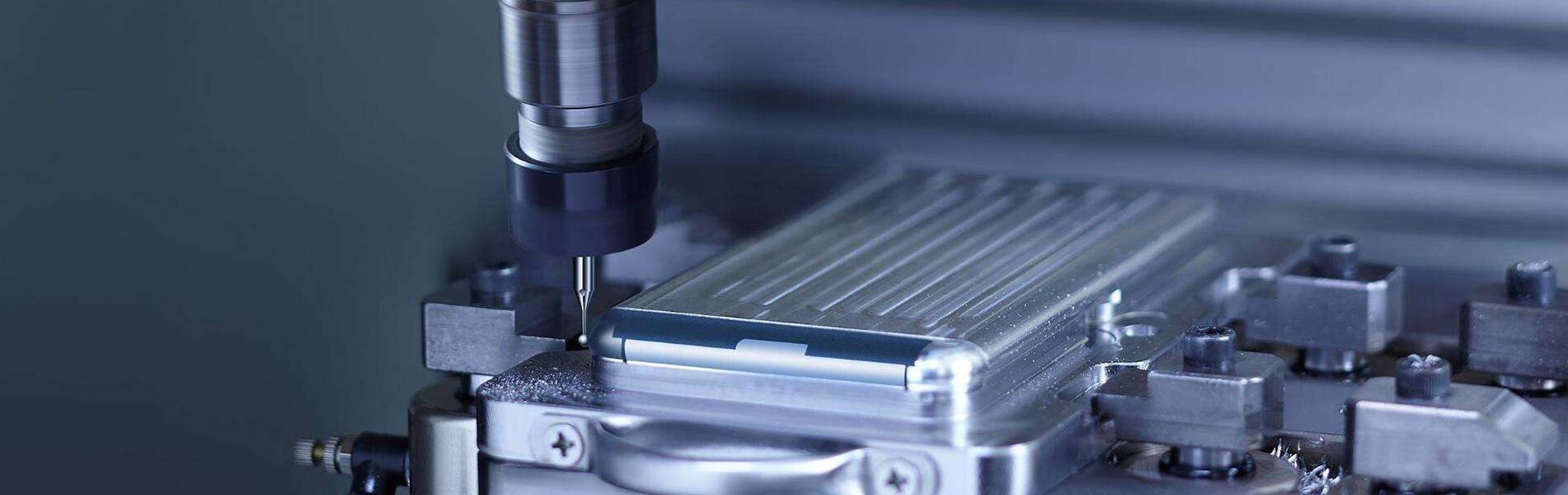

When CNC roughing, we often use dynamic processing technology to improve processing efficiency. So in the more time-consuming finishing process, is there any way to improve the processing efficiency? Mastercam's Accelerated Finishing superstring finishing technology is the programming solution for efficient finishing with arc cutters. For large arc cutters of various shapes, based on the shape of ...

“Which aluminum alloy bends the best?” is a a common question customers want the answer to. In this post, we’ll explain it to you. BACKGROUND In high purity forms, aluminum is soft and ductile. Bending is a delicate and demanding process most of the time and common fabricating processes require a degree of formability that make your choice of proper alloy critical. Depending on designation, alloys...

2

2

pagesCategories

New Blog

© Copyright: 2026 Far East Tech CO., Ltd. All Rights Reserved.

IPv6 network supported