I believe that most customers who process precision mechanical parts will look for local mechanical processing factories to cooperate. This principle of proximity is for convenience, but the region restricts sufficient competition, and the final processing effect of precision mechanical parts is often not very satisfactory. On the premise of maintaining costs, if you want to pursue quality assuran...

Shenzhen Far East Tech as a high tech and innovative CNC Precision Machined Parts manufacturer with over 10 years of experience generating customized CNC machining services, Precision-machined aluminum parts are becoming the choice of many industries.Aluminum is one of the most popular materials due to its excellent mechanical properties.These include affordability, flexibility, durability and cor...

There are many factors that affect the color difference of injection molds. The conventional influencing factors are as follows. 1. Environment - Through years of experience, injection mold manufacturers generally find that the drum is not clean, and the drying hopper has dust, which will cause mold oil pollution. 2. Raw materials - Including toner change, plastic material brand change, fixer chan...

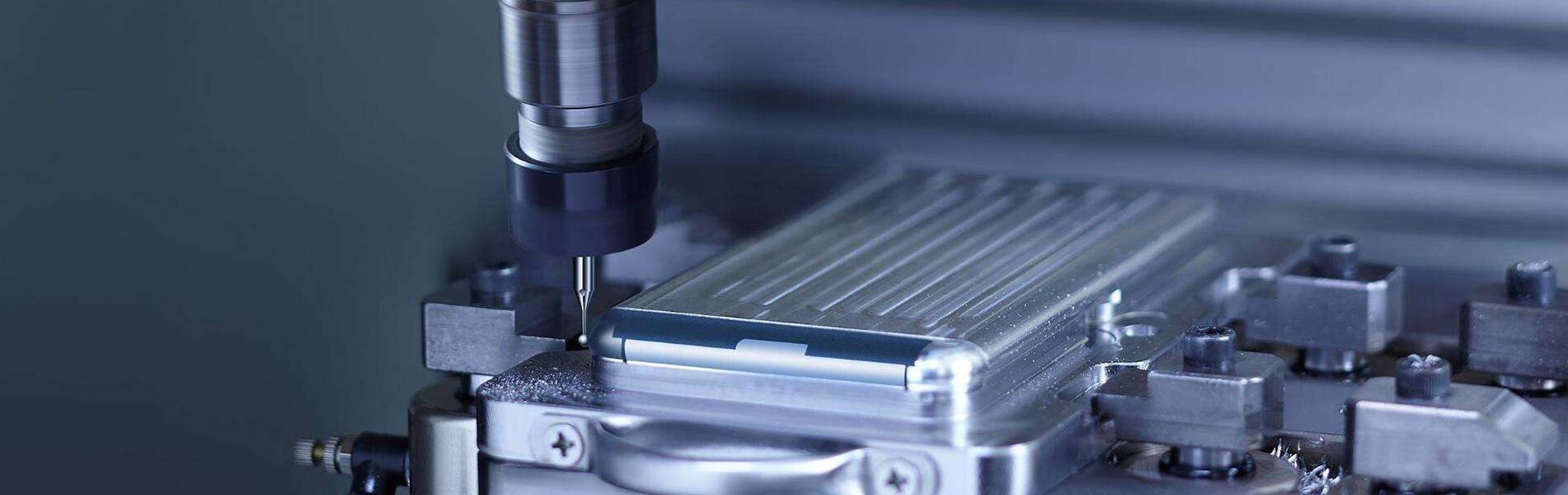

When machining precision injection molds, the molds are divided into upper molds and lower molds, and the molding work is completed in the processing of CNC machine tools. According to the shape of the product, the corresponding male parts are processed. In the fly mold, the assembly completes the precision injection mold. The main points in the machining of precision injection molds are as follow...

Aluminium profile fittings are used to join aluminium profiles to assemble them into the desired profile frame. Conventional aluminum profile accessories include: bolts and nuts, slot connectors, corners, corner brackets, various types of connector plates, and more. Sometimes these parts need to be machined for installation or to optimize the design. Because aluminium profile fittings are cast or ...

Entering the 5G era, artificial intelligence has become the focus of CNC machining enterprises, providing a technical foundation for the transformation and upgrading of these enterprises. According to a survey of CNC machining plants in Shenzhen, 30% of users of CNC lathe machining enterprises that use artificial intelligence on a large scale or adopt artificial intelligence in their core business...

3D printing and CNC machining are relatively common production processes in the field of precision machining. There are similarities and differences between the two. For example, CNC machining is more suitable for mass production. It can create many products in a short time. 3D printing needs It takes hours to create a product. Compared with 3D printing, CNC machining has the following advantages:...

The deformation of parts in machining is difficult to avoid. The main reasons are as follows: The material and structure of the part will affect the deformation of the part. The amount of deformation is proportional to the complexity of the shape, the aspect ratio and the wall thickness, and is proportional to the rigidity and stability of the material. Therefore, the influence of these factors on...

The amount of deformation is proportional to the complexity of the shape, the aspect ratio and the wall thickness, and is proportional to the rigidity and stability of the material. Therefore, the influence of these factors on the deformation of the part should be minimized when designing the part. Especially in the structure of large parts, the structure should be reasonable. Defects such as blan...

Categories

New Blog

© Copyright: 2026 Far East Tech CO., Ltd. All Rights Reserved.

IPv6 network supported