The processing method of precision parts includes using the programmability of the machining center to reasonably compile the numerical control machining program, and optimizing the cutting parameters by utilizing the humanized characteristics of the machining center. Reasonable selection of tool geometry and the use of ordinary high-speed steel drills and end mills to process high-precision and l...

Commonly used heat treatment methods include integral heat treatment, surface heat treatment and deformation heat treatment. The overall heat treatment is the "four fires" that people often hear in the factory, which refers to the four most commonly used heat treatment methods: annealing, normalizing, quenching and tempering. Among them, quenching and tempering are closely related and are often us...

In the processing of precision mechanical parts, many steps are required to produce and process a qualified precision mechanical part. If it is some simple mechanical parts processing, there may only be three or four steps, and complex ones may take as many as ten steps. We determine the processing steps according to the processing technology of mechanical parts. A machining factory of a certain s...

With the development of modern science and technology, the performance of modern industry on the surface of various equipment parts is also getting higher and higher, especially the parts after precision machining, which work under the conditions of high temperature, corrosion, high speed, high pressure, etc. Destruction often starts at the surface. For example, high-temperature oxidation, wear, e...

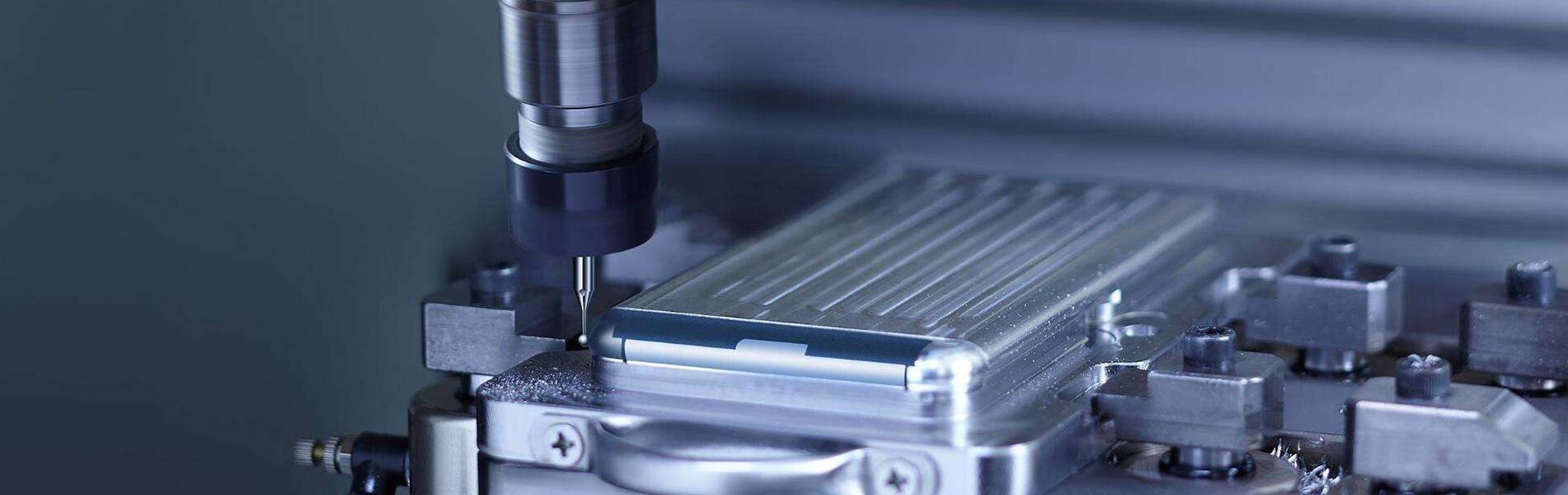

When machining precision injection molds, the molds are divided into upper molds and lower molds, and the molding work is completed in the processing of CNC machine tools. According to the shape of the product, the corresponding male parts are processed. In the fly mold, the assembly completes the precision injection mold. The main points in the machining of precision injection molds are as follow...

Entering the 5G era, artificial intelligence has become the focus of CNC machining enterprises, providing a technical foundation for the transformation and upgrading of these enterprises. According to a survey of CNC machining plants in Shenzhen, 30% of users of CNC lathe machining enterprises that use artificial intelligence on a large scale or adopt artificial intelligence in their core business...

First of all, we all know that in the process of machining mechanical parts, we will inevitably encounter problems in the process of production. Making lathe parts starts with the selection of raw materials. The size and length of the material are related to the process and time of CNC machining. If the material is too long, it will Increase the processing time, the material is too short to be pro...

3D printing and CNC machining are relatively common production processes in the field of precision machining. There are similarities and differences between the two. For example, CNC machining is more suitable for mass production. It can create many products in a short time. 3D printing needs It takes hours to create a product. Compared with 3D printing, CNC machining has the following advantages:...

The deformation of parts in machining is difficult to avoid. The main reasons are as follows: The material and structure of the part will affect the deformation of the part. The amount of deformation is proportional to the complexity of the shape, the aspect ratio and the wall thickness, and is proportional to the rigidity and stability of the material. Therefore, the influence of these factors on...

Categories

New Blog

© Copyright: 2026 Far East Tech CO., Ltd. All Rights Reserved.

IPv6 network supported