What are the development trends of the precision machining industry?

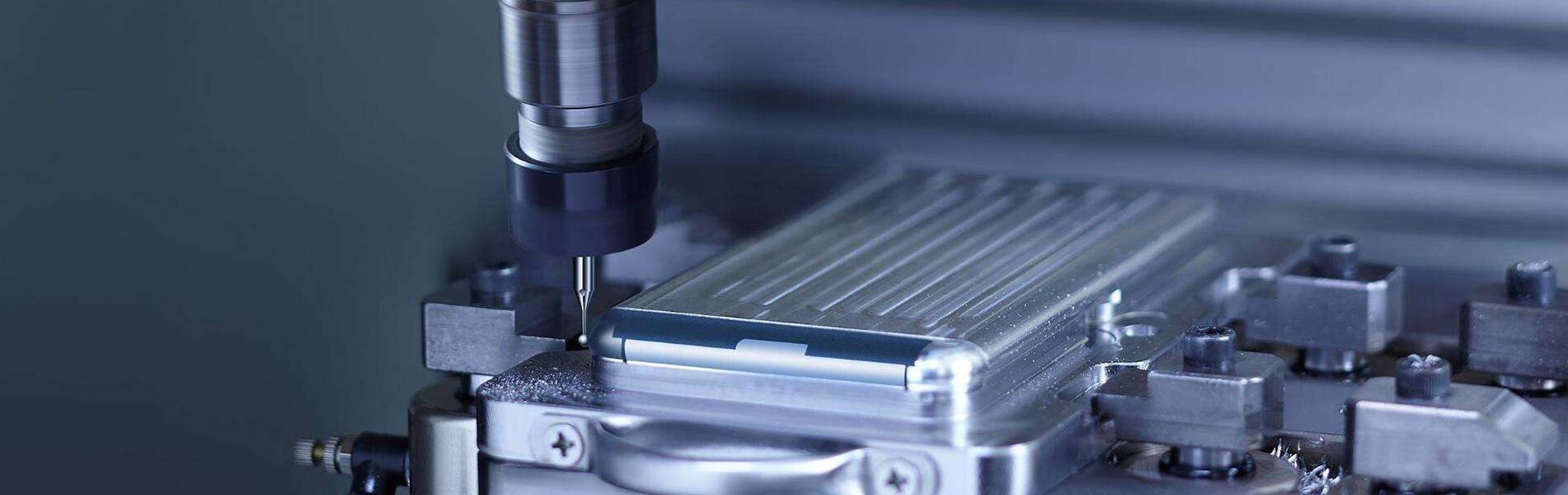

1. The machine tool compound technology is further expanded. With the advancement of CNC machine tool technology, compound machining technology is becoming more and more mature, and the efficiency of precision machining is greatly improved.

2. New breakthroughs have been made in the intelligent technology of CNC machine tools, which have been more reflected in the performance of the CNC system. Such as: automatic adjustment of interference anti-collision function, automatic exit of the workpiece after power failure, power-off protection function, precision machining parts detection and automatic compensation learning function, intelligently improve the function and quality of the machine tool, and there is a five-axis linkage high-speed machining center. 's advent.

4. There has been new progress in the processing technology of precision mechanical parts. The machining accuracy of CNC metal cutting machine tools has been improved to the current micron level, and some varieties have reached about 0.05 μm. The micro cutting and grinding of ultra-precision CNC machine tools can be stable. It reaches about 0.05μm, and the shape accuracy can reach about 0.01μm. The precision of special machining using optical, electrical, chemical and other energy sources can reach nanometer level. technology, so as to enter the era of sub-micron and nano-scale ultra-finishing. The performance of functional components continues to improve, and functional components continue to develop in the direction of high speed, high precision, high power and intelligence, and have achieved mature applications. All-digital AC servo motors and drives, high-tech electric spindles, torque motors, linear The promotion and application of functional components such as motors, high-performance linear rolling components, and high-precision spindle units greatly improves the technical level of CNC machine tools.

Categories

New Blog

© Copyright: 2025 Far East Tech CO., Ltd. All Rights Reserved.

IPv6 network supported