The amount of deformation is proportional to the complexity of the shape, the aspect ratio and the wall thickness, and is proportional to the rigidity and stability of the material. Therefore, the influence of these factors on the deformation of the part should be minimized when designing the part. Especially in the structure of large parts, the structure should be reasonable. Defects such as blan...

Non-standard automation can be customized and designed according to the different requirements and needs of different customers. This is the advantage of non-standard automation equipment to be flexible and adaptable, and it is also an important condition to ensure customer volume and sales. Non-standard automation design services have the following characteristics: 1. Pay attention to the princip...

Hardware parts refer to various metal utensils made of iron, steel, aluminum and other metals through physical processing such as forging, rolling, cutting, etc. The traditional cleaning methods we use are mainly divided into chemical cleaning and physical cleaning according to the different cleaning methods. Chemical cleaning refers to the method of using chemicals or other solvents to remove dir...

The answer is yes. The materials of precision machining parts are divided into two categories: metallic materials and non-metallic materials. For metal materials, the hardness is stainless steel the highest, followed by cast iron, followed by copper, and finally aluminum. The processing of ceramics, plastics, etc. belongs to the processing of non-metallic materials. Manufacturers of precision mach...

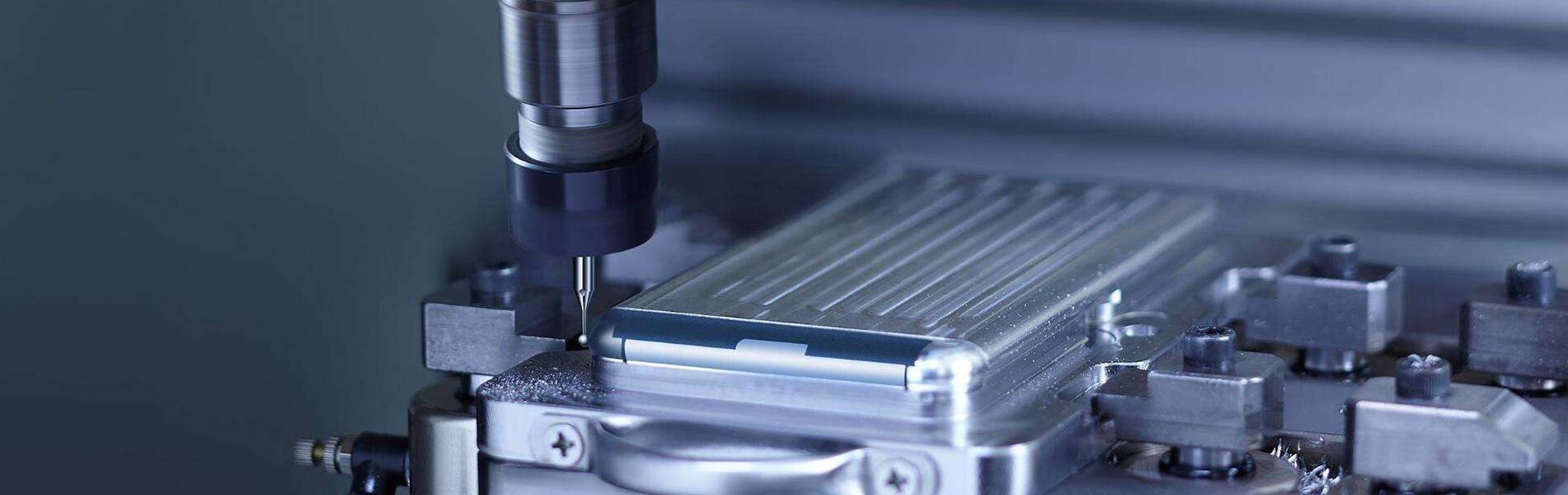

Mill-turn machines are capable of rotating work piece operations (turning) and rotating tool operations, such as milling and cross-drilling, the machine can often be identified as a horizontal or vertical machine, and can be used in some or all tool positions for milling and drilling the spindle. Parts (turning and milling machining part) that require various operations can be machined in one unit...

CNC is short for omputer number control. The direct meaning is that it is computer numerical control, which is a processing technology widely used in the manufacturing industry. It can also be said to be the symbol of the current manufacturing industry. CNC can easily realize multi-axis linkage Simultaneous processing is performed on multiple coordinate axes (including linear coordinates and rotat...

As we all know, production safety refers to the relevant activities that take corresponding accident prevention and measures in order to avoid accidents that cause personal injury and property loss in production and operation activities, so as to ensure the personal safety of employees and ensure the smooth progress of production and operation activities. Then the CNC machining commonly used in th...

Precision welding is suitable for various precision welding processes including circular seam automatic rail welding and laser welding. Precision Welding can be used to weld small tubes up to 0.012" diameter and 0.001" wall thickness. Almost all metals can be precision welded, including titanium alloys and nickel-based alloys. Precision welding technology is widely used in aerospace and energy fie...

As we all know, grinding is the smoothing and precision machining of the surface of the part. The abrasive particles coated or pressed on the grinding tool are used to complete the processing through the relative movement of the grinding tool and the workpiece under a certain pressure. Some people think that grinding and polishing are the same, but grinding and polishing are two different processi...

Categories

New Blog

© Copyright: 2026 Far East Tech CO., Ltd. All Rights Reserved.

IPv6 network supported