With the outbreak of the global COVID-19 epidemic in early 2020, the global demand for masks has surged, which makes the mask machine a hot device. The key to the production of masks is inseparable from precision micro-hole processing technology and micro-hole drilling machine, of which precision micro-hole processing involves melt-blown micro-hole processing and drilling. So what are the technica...

I believe that most customers who process precision mechanical parts will look for local mechanical processing factories to cooperate. This principle of proximity is for convenience, but the region restricts sufficient competition, and the final processing effect of precision mechanical parts is often not very satisfactory. On the premise of maintaining costs, if you want to pursue quality assuran...

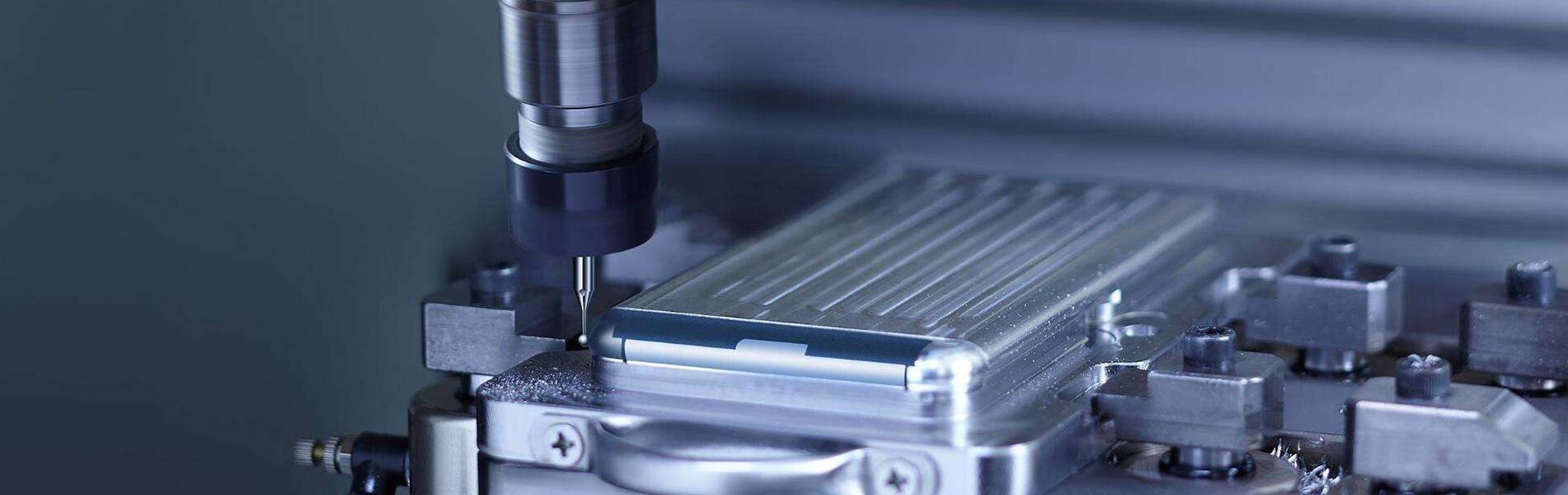

Shenzhen Far East Tech as a high tech and innovative CNC Precision Machined Parts manufacturer with over 10 years of experience generating customized CNC machining services, Precision-machined aluminum parts are becoming the choice of many industries.Aluminum is one of the most popular materials due to its excellent mechanical properties.These include affordability, flexibility, durability and cor...

Stainless steel precision parts have excellent corrosion resistance, formability, compatibility, and toughness in a wide temperature range. Therefore, they are widely used in heavy industry, light industry, daily necessities industry, building decoration and other industries. Due to the above-mentioned characteristics of stainless steel, it is more and more widely used in aviation, aerospace, chem...

Copper is a truly versatile metal.we often use copper materials to machine parts.there are many benefits to using copper for machined parts.Copper is one of the most versatile metals in the world, with high resistance to corrosion and great electrical and thermal conductivity.Far East Tech usually uses CNC Milling and CNC Turning for Machining Copper parts. In this article, we will mainly discuss ...

We all know that CNC machining center is a high-speed cutting processing equipment. Once an accident occurs under high-speed operation, it will often cause very serious consequences. Therefore, the protective cover of the machining center is an indispensable protective equipment. The protective cover of the cnc machining center can be divided into internal protection and external protection accord...

The processing method of precision parts includes using the programmability of the machining center to reasonably compile the numerical control machining program, and optimizing the cutting parameters by utilizing the humanized characteristics of the machining center. Reasonable selection of tool geometry and the use of ordinary high-speed steel drills and end mills to process high-precision and l...

Commonly used heat treatment methods include integral heat treatment, surface heat treatment and deformation heat treatment. The overall heat treatment is the "four fires" that people often hear in the factory, which refers to the four most commonly used heat treatment methods: annealing, normalizing, quenching and tempering. Among them, quenching and tempering are closely related and are often us...

In the processing of precision mechanical parts, many steps are required to produce and process a qualified precision mechanical part. If it is some simple mechanical parts processing, there may only be three or four steps, and complex ones may take as many as ten steps. We determine the processing steps according to the processing technology of mechanical parts. A machining factory of a certain s...

Categories

New Blog

© Copyright: 2026 Far East Tech CO., Ltd. All Rights Reserved.

IPv6 network supported