Shenzhen Far East Excellence Technology Co., Ltd. is a powerful manufacturer specializing in high-precision CNC machining. It owns more than 200 imported CNC machining centers, cutting machines, turning and milling machining centers. We most know that the CNC machining industry know that the precision of CNC machining is divided into levels. Next, Far East Tech Precision Technology will take you t...

In the high-temperature heat dissipation system, some high-precision micro-porous parts are often needed. Today, let's take a look at how Far East Tech manufactures these parts. Take Item No.#13932 (High Precision Micro Porous Part) as an example. The part material is AISI420. The processing techniques involve: CNC precision machining, precision CNC turning, precision grinder grinding, laser ...

We all know that CNC machining center is a high-speed cutting processing equipment. Once an accident occurs under high-speed operation, it will often cause very serious consequences. Therefore, the protective cover of the machining center is an indispensable protective equipment. The protective cover of the cnc machining center can be divided into internal protection and external protection accord...

Commonly used heat treatment methods include integral heat treatment, surface heat treatment and deformation heat treatment. The overall heat treatment is the "four fires" that people often hear in the factory, which refers to the four most commonly used heat treatment methods: annealing, normalizing, quenching and tempering. Among them, quenching and tempering are closely related and are often us...

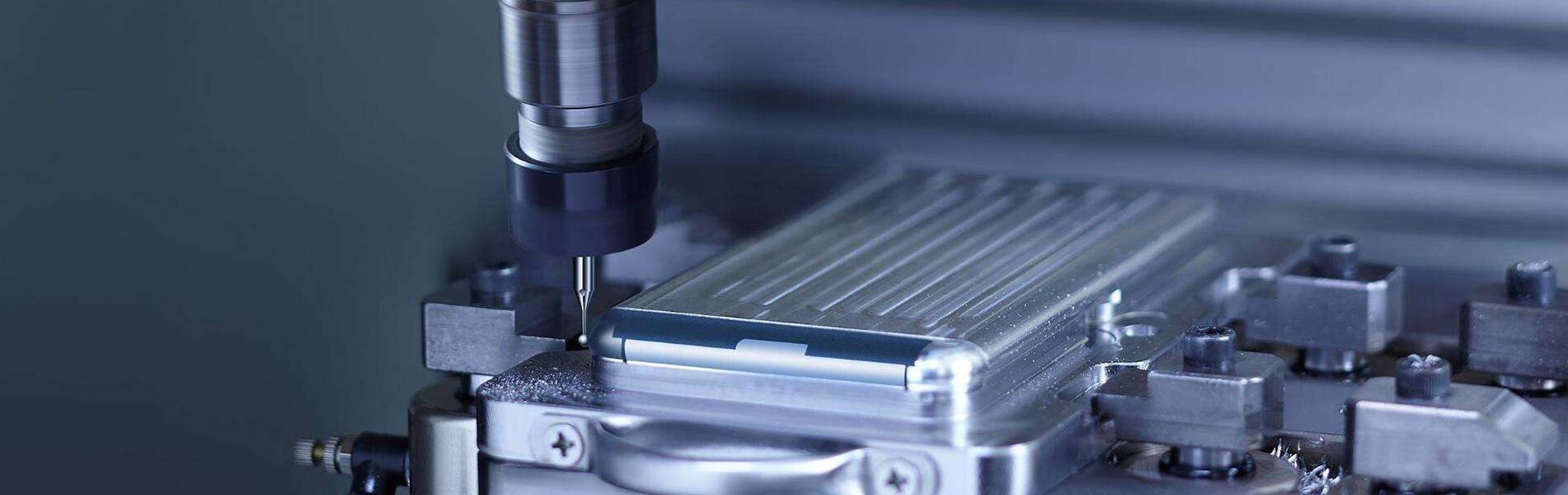

When machining precision injection molds, the molds are divided into upper molds and lower molds, and the molding work is completed in the processing of CNC machine tools. According to the shape of the product, the corresponding male parts are processed. In the fly mold, the assembly completes the precision injection mold. The main points in the machining of precision injection molds are as follow...

It is well known that heat treatment is a common method for changing the mechanical properties of certain metals. Being able to change the hardness, toughness, and strength of a metal while keeping its chemical composition intact and nearly unchanged is a great way to tailor a metal to the needs of the environment and job. There are many different ways to heat treat metals, the most popular of whi...

The last article introduced what quenching is, and now let's share the application of quenching. The quenching process is widely used in the modern machinery manufacturing industry. Important parts in machinery, especially steel parts used in automobiles, airplanes, and rockets, are almost all quenched. In order to meet the various technical requirements of various parts, various quenching process...

Precision machined parts will have a certain degree of wear after assembly and operation. Heat treatment can enhance the hardness of the workpiece, increase the wear resistance of the workpiece and prolong the life of the workpiece. In this article, we will introduce to you what is vacuum heat treatment processing technology. Next week, we will introduce the characteristics of vacuum heat treatmen...

With the development of production and science and technology, machining industry is becoming more and more important in human society. With the vigorous development of information technology, electronic technology, sensor technology and other subdivisions, automation technology also plays a decisive role in mechanical processing and manufacturing. While saving the cost of mechanical processing an...

1

pagesCategories

New Blog

© Copyright: 2025 Far East Tech CO., Ltd. All Rights Reserved.

IPv6 network supported