As the COVID-19 spreads around the world, various raw material costs, transportation costs and labor costs have been rising rapidly. At the same time, in order to relieve pressure on energy supply and achieve the “double carbon”(carbon peak, carbon neutral) strategic goal, a stricter power rationing has been implemented. Under the dual predicament of the epidemic and power rationing, how can compa...

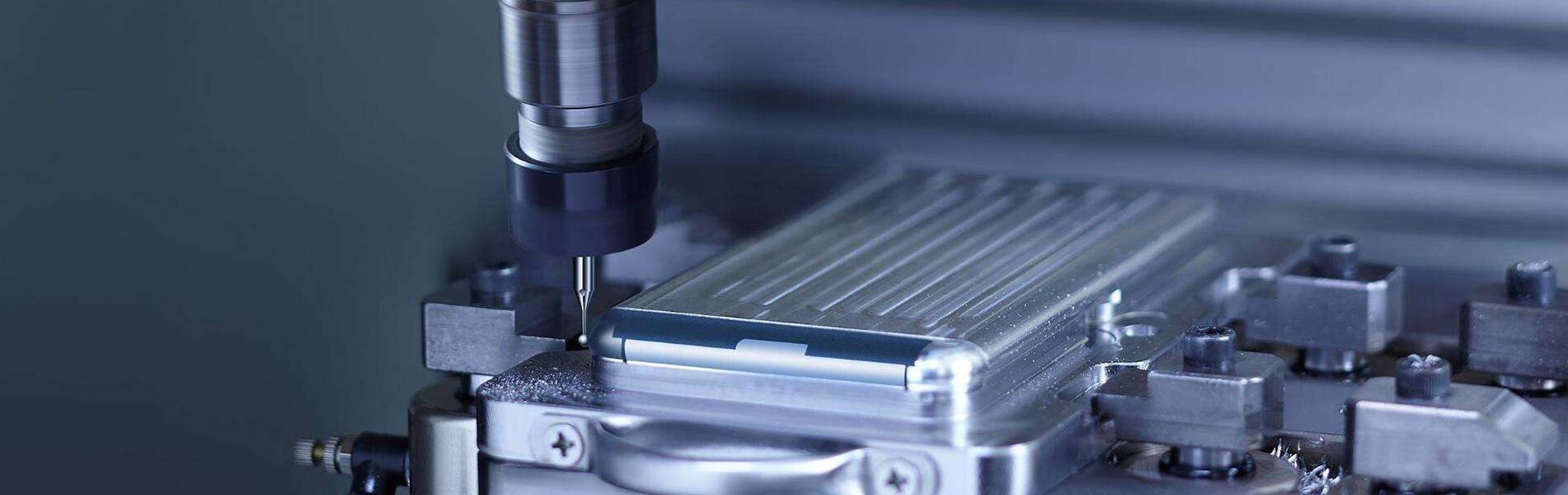

Shenzhen Far East Tech Co., Ltd has sufficient precision production and processing equipment,a strict internal quality management system and a high-tech industry 4.0 smart factory data production system.CNC machines have become a standard in the machining industry. Their accuracy, speed, and ease of use make them indispensable tools. But despite these advantages, they’re still not perfect. Quality...

In the process of workpiece processing, auxiliary time such as workpiece loading and unloading, tool adjustment, etc., account for a considerable proportion of the processing cycle. The tool adjustment is time-consuming and laborious, and not easy to be accurate, and finally requires trial cutting. Statistics show that for the processing of a workpiece, pure maneuvering time only accounts for 55% ...

Stainless steel precision parts have excellent corrosion resistance, formability, compatibility, and toughness in a wide temperature range. Therefore, they are widely used in heavy industry, light industry, daily necessities industry, building decoration and other industries. Due to the above-mentioned characteristics of stainless steel, it is more and more widely used in aviation, aerospace, chem...

In the high-temperature heat dissipation system, some high-precision micro-porous parts are often needed. Today, let's take a look at how Far East Tech manufactures these parts. Take Item No.#13932 (High Precision Micro Porous Part) as an example. The part material is AISI420. The processing techniques involve: CNC precision machining, precision CNC turning, precision grinder grinding, laser ...

Copper is a truly versatile metal.we often use copper materials to machine parts.there are many benefits to using copper for machined parts.Copper is one of the most versatile metals in the world, with high resistance to corrosion and great electrical and thermal conductivity.Far East Tech usually uses CNC Milling and CNC Turning for Machining Copper parts. In this article, we will mainly discuss ...

The processing method of precision parts includes using the programmability of the machining center to reasonably compile the numerical control machining program, and optimizing the cutting parameters by utilizing the humanized characteristics of the machining center. Reasonable selection of tool geometry and the use of ordinary high-speed steel drills and end mills to process high-precision and l...

Commonly used heat treatment methods include integral heat treatment, surface heat treatment and deformation heat treatment. The overall heat treatment is the "four fires" that people often hear in the factory, which refers to the four most commonly used heat treatment methods: annealing, normalizing, quenching and tempering. Among them, quenching and tempering are closely related and are often us...

In the processing of precision mechanical parts, many steps are required to produce and process a qualified precision mechanical part. If it is some simple mechanical parts processing, there may only be three or four steps, and complex ones may take as many as ten steps. We determine the processing steps according to the processing technology of mechanical parts. A machining factory of a certain s...

Categories

New Blog

© Copyright: 2025 Far East Tech CO., Ltd. All Rights Reserved.

IPv6 network supported