One of the ways to restore a failed precision mechanical part is to use thermal spraying. First of all, the surface of the workpiece needs to be pretreated, and the degree of bonding between the coating and the base material (workpiece material) is the key. If the bonding cannot be performed or the bonding strength is not enough, the spray coating will be peeled off from the substrate, failing to ...

Electroless nickel plating technology is a method in which metal salts and reducing agents are used to obtain coatings by autocatalytic reactions on the surface of materials. So far, electroless nickel plating is one of the fastest growing surface treatment processes and has the widest range of applications. It can make the machined precision parts more wear-resistant and durable. The rapid develo...

The last article introduced what is electroless nickel plating, and this article will introduce the related process of nickel plating. Electroless nickel plating and electroplating nickel are both nickel plating processes, but they are very different. 1. The principle difference between electroless plating and electroplating is that electroplating requires additional current and anode, while elect...

Mirror polishing is a polishing process that makes the surface of the product show a mirror effect. It is mainly used to reduce the surface roughness of the workpiece. When selecting a polishing process for a metal workpiece, different methods can be selected according to different needs. This process is usually used in elevators. Cars, aerospace equipment accessories, molds, auto parts, medical m...

The mirror polishing process is mainly used to reduce the surface roughness of the workpiece. When selecting a polishing process for a metal workpiece, different methods can be selected according to different needs. The following are several common methods of polishing mirror processing. 1. Mechanical polishing Mechanical polishing is a polishing method that obtains a smooth surface by cutting and...

Precision machined parts will have a certain degree of wear after assembly and operation. Heat treatment can enhance the hardness of the workpiece, increase the wear resistance of the workpiece and prolong the life of the workpiece. In this article, we will introduce to you what is vacuum heat treatment processing technology. Next week, we will introduce the characteristics of vacuum heat treatmen...

We introduced what is vacuum heat treatment in the last batch of articles, and now let's introduce the characteristics of vacuum heat treatment. The vacuum state is an excellent protective environment. The mechanical parts after heat treatment in the vacuum environment are smooth and bright in appearance, the internal structure has been changed, and the mechanical properties are excellent. Its cha...

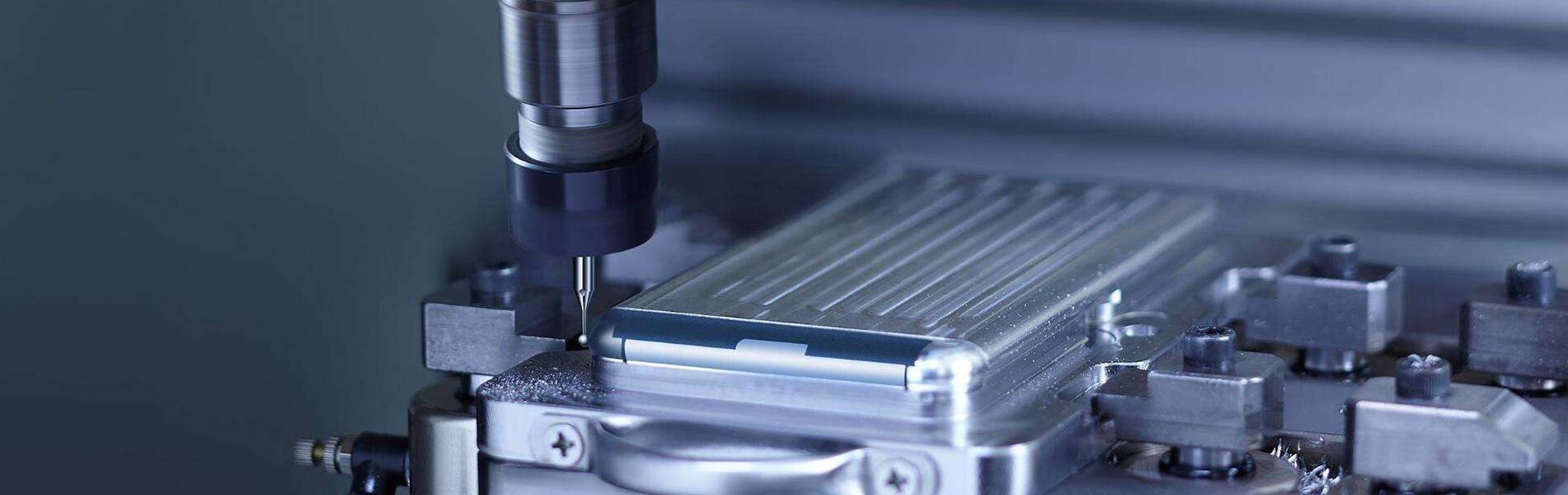

Precision hardware parts processing is a production process that requires very high precision of spare parts. In the process of processing and producing precision hardware parts, the precision must be strictly controlled to ensure that qualified hardware parts are made. So what are the processes of precision hardware parts processing? 1. First of all, you must be familiar with the processing equip...

The definition of the burr Burr is a protrusion of a material, such as metal or resin that is generated when it is processed. Burrs are created from shearing, bending, cutting, piercing, and compressing materials that are mostly seen on soft and ductile materials. About the burr size, we express burr size by its height, thickness and length. And the deburring is a secondary operation of a machinin...

Categories

New Blog

© Copyright: 2025 Far East Tech CO., Ltd. All Rights Reserved.

IPv6 network supported